Page Navigation

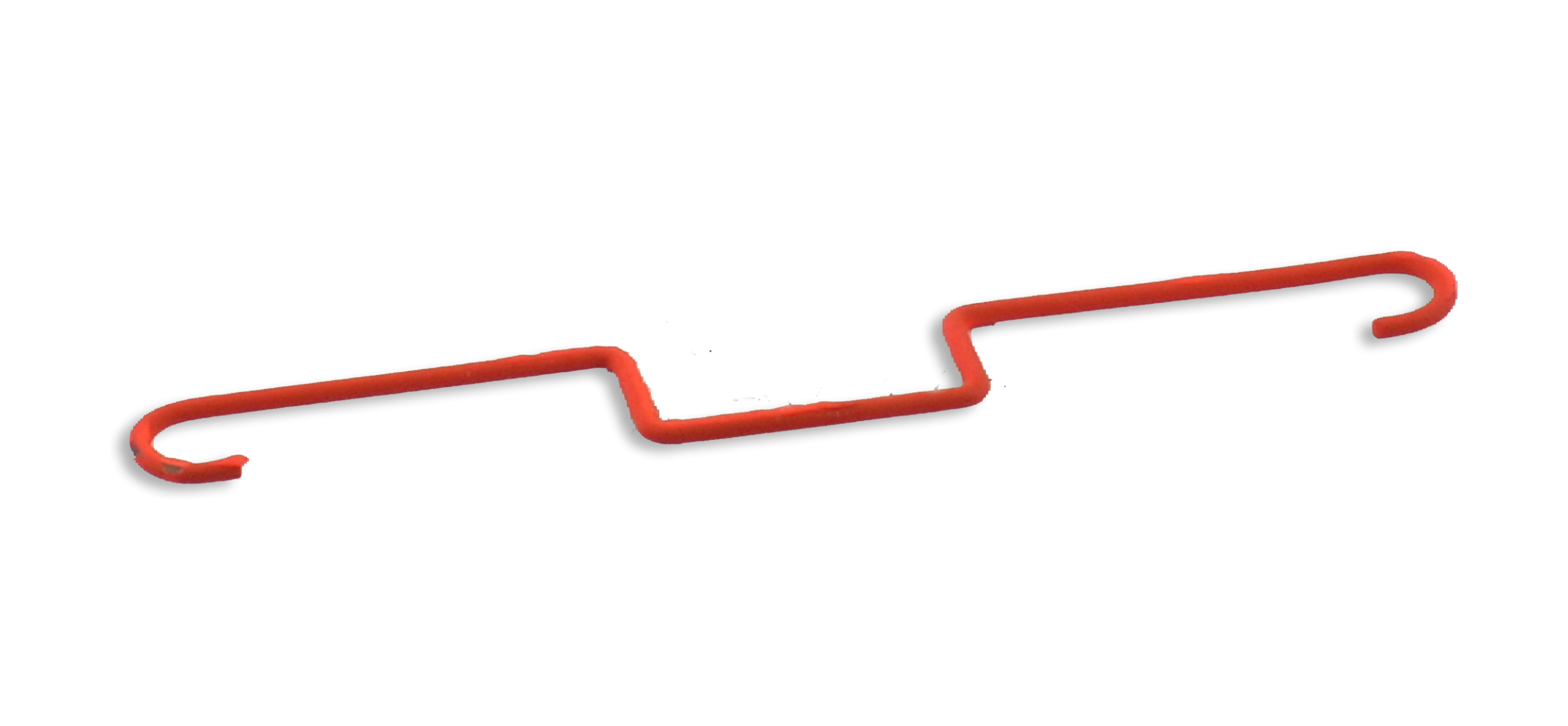

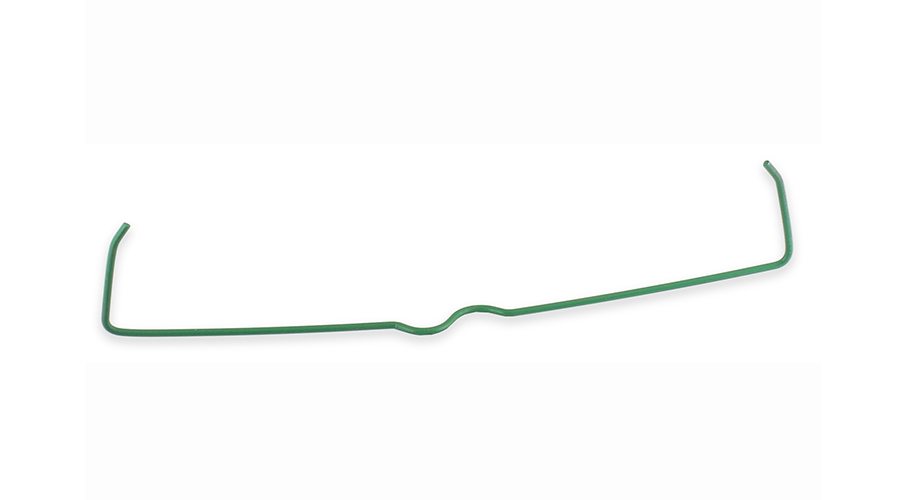

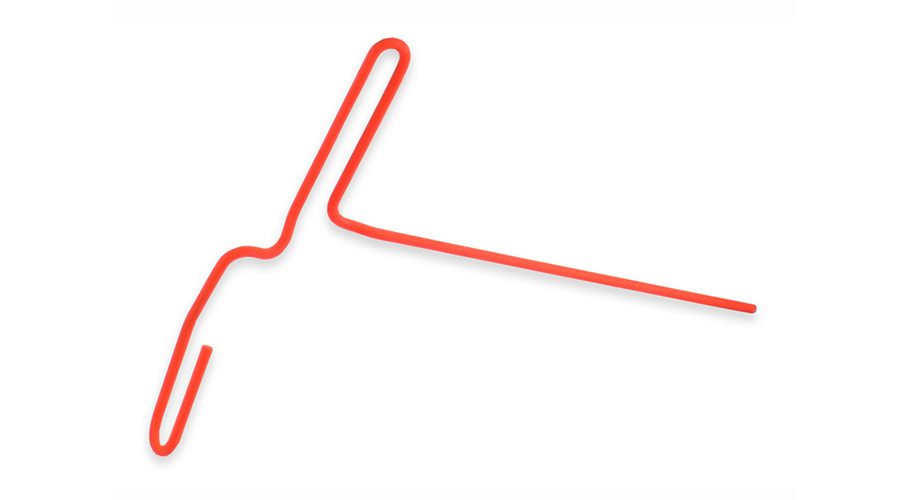

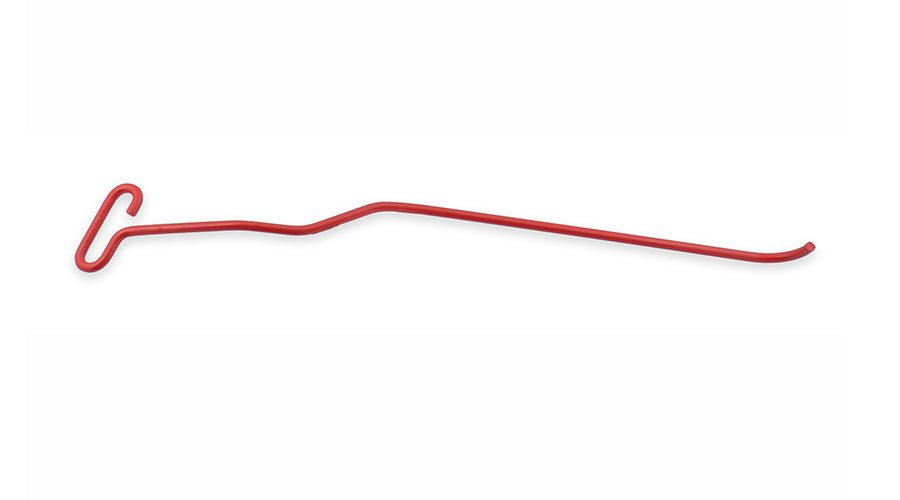

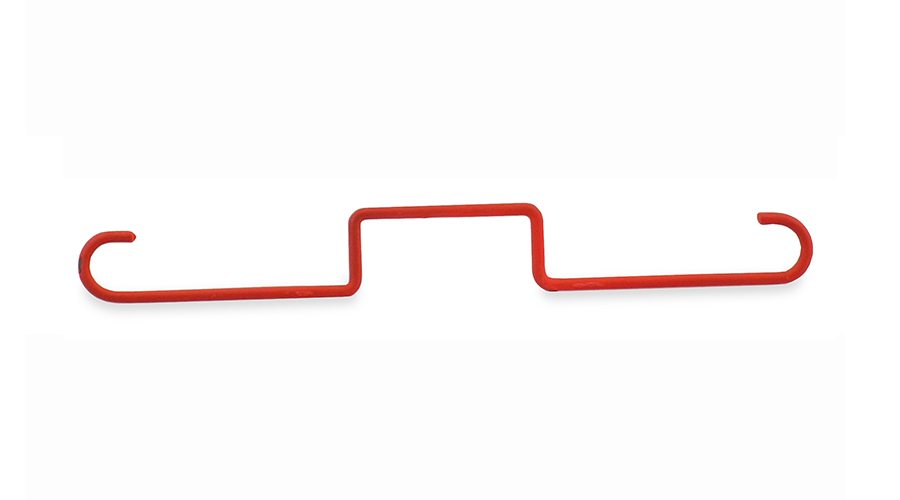

Wire Forms

KEY PRODUCT HIGHLIGHTS

Wire forms can be manufactured to any shape possible

Wire forms can be simple beams or cantilever designs, or complex configurations including multi-pane bending.

They retain components in position and allow for limited deflection

Wire forms can be made by round, rectangular, or square wire

Alloy material range from low-cost carbon steels through super alloys such as titanium

Wire size: .005” to .626”

Wire Forms

MATERIALS, USAGE & SPECIFICATIONS

We most commonly use the following types of alloys in our flagship and custom products: carbon steel, alloy steel, stainless steel, nickel-based, cobalt-based, copper-based, and titanium. To view our full materials list, click on the click below.

View Materials ListCommercial Aviation & Space

Explore Industry >>

Defense

Explore Industry >>

Energy, Gas & Mining

Explore Industry >>

General Manufacturing

Explore Industry >>

Medical

Explore Industry >>

Nuclear

Explore Industry >>