Our Prototyping Process

Solving Design Problems Through Collaboration

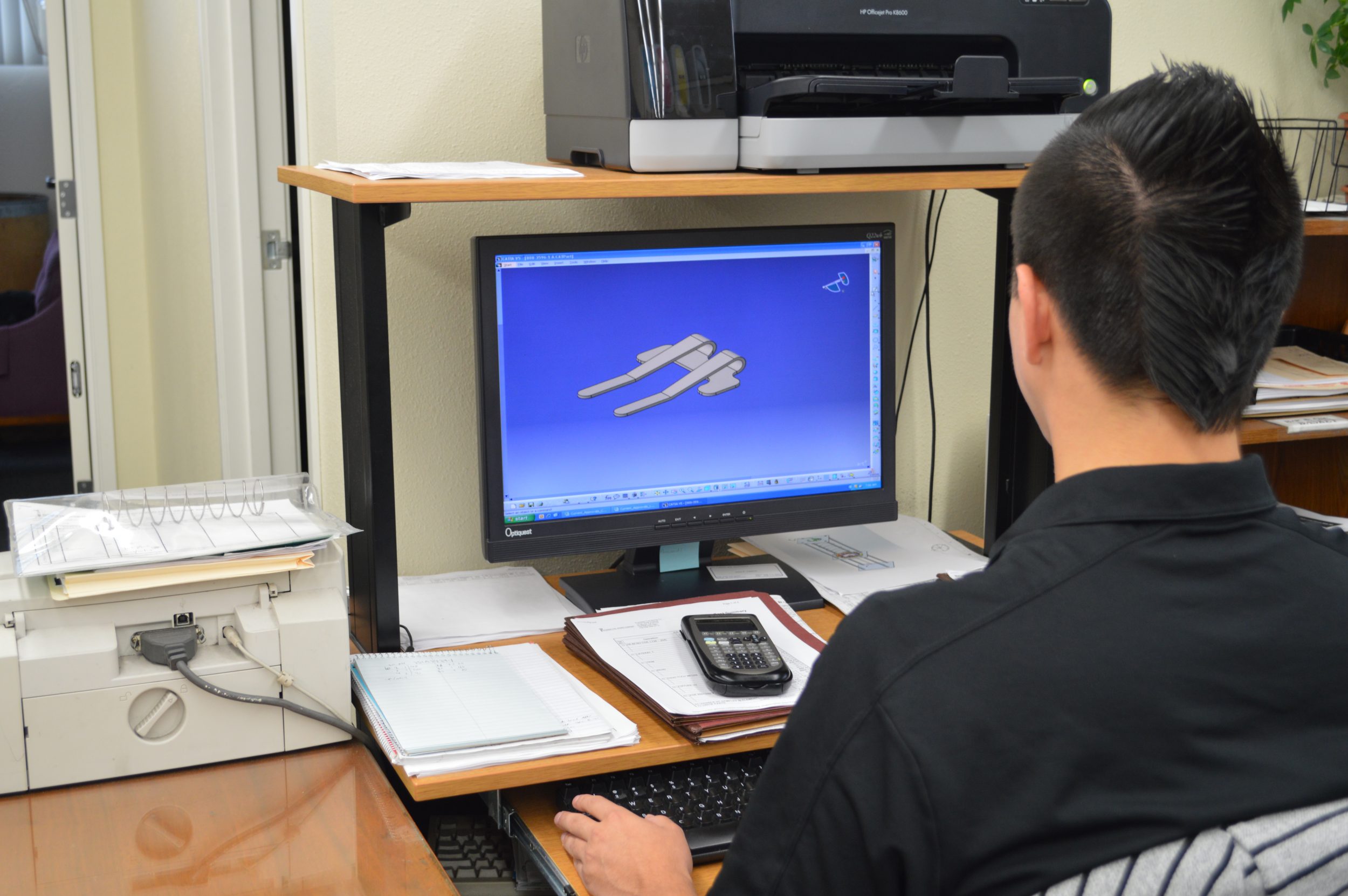

Our years of experience has resulted in PCS creating a short-run production department that allows us to make low-volume parts that meet very specific dimensional and functional requirements Our engineers collaborate closely with our customers to help to solve the most difficult design problems, allowing us to produce almost any shape and geometric feature required.

We optimize the design for manufacturability and assembly, and test through the use of our Advanced Spring Design software. Following the design phase, we supply our customers with parts for testing and verification within their application. During this phase, we work closely with our customer to solve potential issues and arrive at cost-effective solutions required for production.

Prototyping

Key Highlights

-

Proven Collaborative Process

Our collaborative and iterative process ensures that your new product will be taken from the prototype stage to the production stage successfully and quickly.

-

Thorough Testing

We have our customers test their parts in real time to identify any potential issues. The information collected during this phase can be used to optimize the part design and manufacturability achieving the most cost-effective end-result.

-

Cost Effective & On-Time Delivery

Resolving potential issues at the beginning of the process promotes cost-effectiveness and on-time deliveries, allowing you to get your product ready for mass production as quickly as possible.